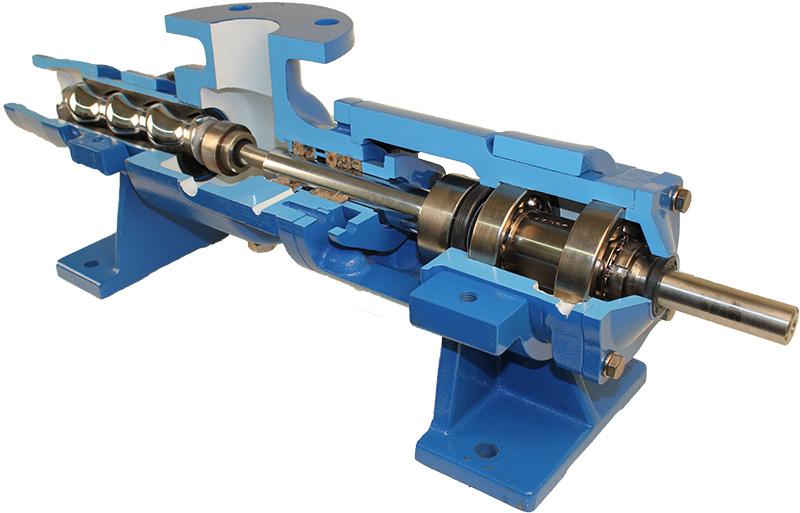

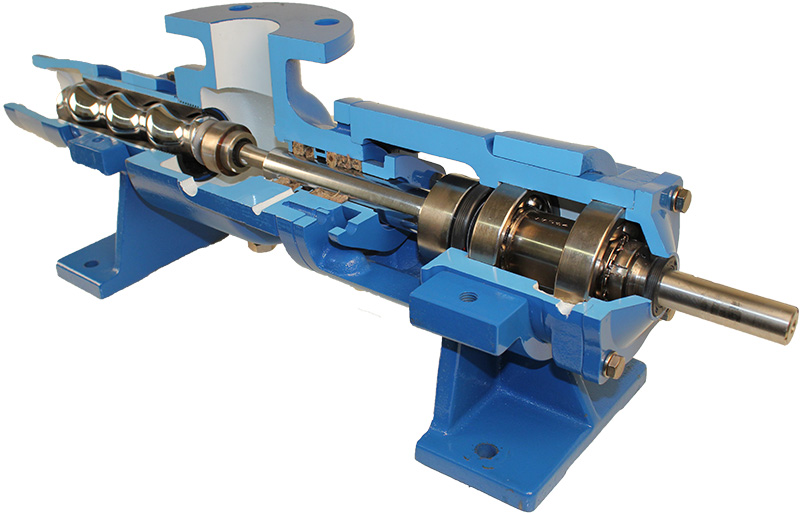

Both rotor-stator pumps and positive displacement pumps, also known as progressing cavity pumps, are capable of effectively transferring mediums with low to medium viscosity while maintaining a very high percentage of efficiency. These pumps are also known as rotor-stator pumps. To take advantage of the fact that Mingjie Pump (www. mingjiepump. com) is one of the most well-known manufacturers and suppliers of progressing cavity pumps, we would like to take this opportunity to share with you some insights regarding the effectiveness of progressing cavity pumps in this article. The medium can be transported from the suction port to the pressure port using progressive cavity pumps. This is accomplished by forming a series of sealed cavities between the rotor and the stator of the pump. The cavities move in an elliptical motion that is progressive, which allows this to be accomplished. In terms of efficiency, progressing cavity pumps have a number of advantages that other types of pumps, such as centrifugal pumps, do not have.

These advantages are not shared by other types of pumps. It is possible to attribute the high efficiency of progressing cavity pumps to a number of influential factors, some of which are as follows:

Modification of the medium with extreme caution:In progressive cavity pumps, the medium is transferred because progressive sealing cavities are formed between the rotor and the stator.

These cavities are located between the two components. Because of this, the pumps are able to avoid turbulent flow and high shear stress, both of which are characteristics of centrifugal pumps when they are in operation. This sensitive handling has the potential to significantly reduce the amount of friction and internal leaks, which will ultimately result in an increase in efficiency. The amount of mechanical friction loss that is experienced by progressing cavity pumps is significantly lower than that which is experienced by reciprocating pumps. This occurs as a result of the distinctive trochoid shape that the pump possesses. In comparison to screw pumps, the amount of contact that takes place between the rotor and the stator in a rotary pump is significantly less. There is a correlation between reduced friction and increased efficiency. When it comes to progressing cavity pumps, the fit between the rotor and the stator is of utmost importance because of the low slip rate that these pumps have. When clearance and surface finish are optimized, it is possible to achieve a lower slip rate, which is defined as the difference between the theoretical flow rate and the actual flow rate.

This can be accomplished by optimizing clearance and surface finish. It is possible that a low slip rate contributor is responsible for the increased pumping efficiency obtained.

Extremely high efficiency in terms of volume:

Progressive cavity pumps are able to achieve volumetric efficiency levels as high as 95-98% because they minimize leakage on both the internal and external sides of the pump. Because progressive cavities are able to provide reliable sealing and ensure that the majority of the pumped volume is effectively delivered, the overall pumping efficiency is significantly increased. This comes about as a result of the progressive cavities' ability to provide reliable sealing. As a result of the fact that progressive cavity pumps do not call for a significant amount of starting torque, they are able to start and run without causing any sudden impact on the drive. This allows for continuous operation and smooth starting. Furthermore, there is no pulsation, and the movement of both the rotor and the stator is continuous to the same degree. The smooth operation of a machine is directly proportional to its level of efficiency, both in terms of its hydraulic and mechanical performance.

Unlike reciprocating pumps, progressing cavity pumps are able to keep their efficiency at a high level across a wider range of flow rates without the need to adjust the pump size. This is in contrast to reciprocating pumps, which require the pump size to be adjusted. Modifying the flow through the application of speed variation is one method that can be utilized to achieve additional optimization of efficiency. The progressive motion of progressive cavity pumps makes it unnecessary for the foot valve to be primed before the pumps are started up. This is because progressive cavity pumps have the capability of self-priming. There is no priming loss that takes place when it is applied in self-priming applications like dewatering, which contributes to a higher overall efficiency. Some examples of these applications include.

Pumping at a high viscosity:

The viscosity of the medium that can be effectively handled by progressive cavity pumps is several times higher than the viscosity that centrifugal pumps are able to handle. Progressive cavity pumps continue to uphold an exceptional level of efficiency even when working with extremely viscous fluids. This is due to the fact that the pumping process does not result in the production of turbulence.

The company mingjie progressive cavity pump is dedicated to conducting ongoing research and development in order to make the most of the inherent benefits that are associated with the development of cavity pumps.

When it comes to the production of rotor-stator sets, we make use of high-precision machining technologies to guarantee that the clearances and surface finishes are optimized in order to minimize slippage to the greatest extent possible. It is necessary to conduct exhaustive hydraulic and mechanical tests in order to evaluate the volumetric efficiency, friction loss, and to guarantee that the product is of a high performance level. For progressive cavity pump applications can be found in a wide range of industries, such as the chemical industry, the food processing industry, mining, and other industries that require high efficiency in the transfer of medium. These industries include the chemical industry, the food processing industry, and the mining industry. In a nutshell, progressive cavity pumps have a remarkable capability that enables them to handle a wide variety of media with high viscosity in a gentle, efficient, and dependable manner. There are many different types of media that can be handled by these pumps.

By optimizing the design and manufacturing of the rotor-stator combination, it is possible to achieve a significant level of efficiency in comparison to other types of pumps. This is true in comparison to other types of pumps. In our capacity as a manufacturer, Mingjie Pump is dedicated to the production of cutting-edge cavity pumps that carry out their functions at an efficiency level that is at the forefront of the industry. This is done for the benefit of our customers. When it comes to the improvement of cavity pump efficiency, we hope that this article has provided some information that is helpful to you. It is imperative that you do not be reluctant to get in touch with us in the event that you require any progressing cavity pumps or have any other questions.