In circumstances where critical piping systems require the strength, reliability, and safety assurance that welded flange connections provide, ASME B16.47 Series B Weld Neck Flanges are the ideal solution. These flanges allow for connections to be made without the need for welding. As an industry-leading manufacturer and supplier, Carbonsteelflanges. com offers a comprehensive portfolio of ASME/ANSI B16.47 Series B Weld Neck Flange. These flanges are fabricated to the highest standards using the most cutting-edge manufacturing techniques. In this article, we will investigate the reasons why specifying B16.47 Series B Weld Neck Flanges from Carbonsteelflanges. com offers the highest level of code compliance, quality, and dependable performance. Specifically, we will look at the reasons why these components are so important.

Materials, in addition to the ability to trace

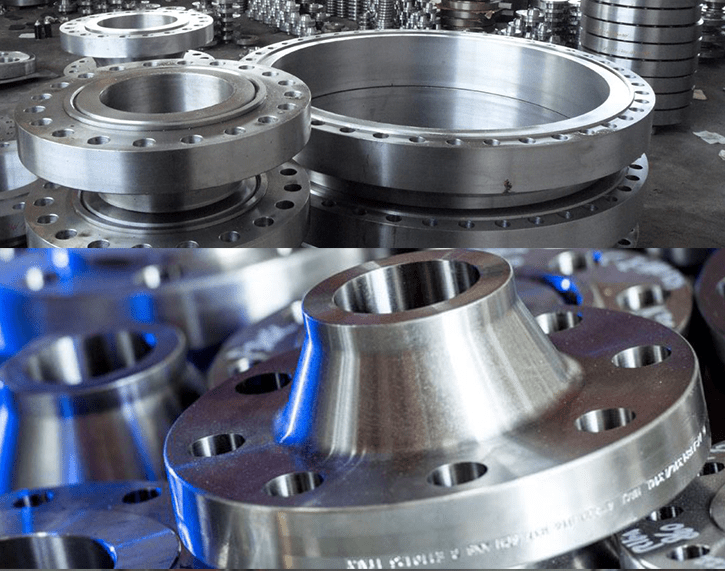

Carbonsteelflanges is a supplier of high-quality carbon steel, stainless steel, and alloy materials for the production of flanges that conform to standards such as ASTM A105, A182, and B16.47 Class 150-2500. These flanges are used in aerospace, automotive, and other industries. The chemical and mechanical properties are subjected to stringent material control procedures and certification from an independent third party in order to ensure that they are accurate. Furthermore, there is the possibility of providing validated test data and specifications for the custom alloys that are manufactured. Customers are provided with exhaustive documentation of the traceability of the materials, which ensures that the materials satisfy all of the requirements that are stipulated by the codes and international quality standards. Preciseness in each and every measurementThe B16.47 standard is a set of dimensions that establishes dimensions for nominal sizes that range from 1.5 degrees to 60 degrees. In order to machine flanges to the precise dimensional tolerances that are required by the standard, Carbonsteelflanges uses cutting-edge CNC machinery to perform the machining process incredibly carefully. These tolerances encompass everything from the overall diameters and thicknesses to the precise locations of the bolt holes. They also include the overall diameters. This not only ensures that the components can be interchanged, but it also ensures that they have the ability to seal properly.

Evaluating the Level of PressureIn accordance with the temperature curves presented in B16.47, maximum pressure ratings for flanges can range anywhere from 150 to 2500 pounds per square inch. Both the type of material and the minimum thickness are taken into consideration when determining these ratings. Additionally, higher ratings that make use of specialized alloys and thickness are qualified by applying rigorous pressure testing. This is done in order to ensure that the specifications are met. The flanges that are manufactured by Carbonsteelflanges are dependable in the sense that they are able to function safely under conditions that are higher than the greatest possible code rating. Fabrication's Superiority in Every AspectCarbonsteelflanges is able to manufacture flanges by employing either the precision casting or forging techniques, both of which are governed by a quality system that is certified by the International Organization for Standardization (ISO). Following the completion of secondary machining, the flange faces and weld neck projections were finished to the specifications that were specified for flatness, perpendicularity, and surface finishes. There are additional methods that guarantee the absence of defects in products, such as passivation and complete non-destructive testing.

Fabrication's Superiority in Every AspectCarbonsteelflanges is able to manufacture flanges by employing either the precision casting or forging techniques, both of which are governed by a quality system that is certified by the International Organization for Standardization (ISO). Following the completion of secondary machining, the flange faces and weld neck projections were finished to the specifications that were specified for flatness, perpendicularity, and surface finishes. There are additional methods that guarantee the absence of defects in products, such as passivation and complete non-destructive testing.

Qualifications Required for the InspectionIt is the responsibility of qualified Level II and III technicians to perform one hundred percent volumetric (RT) and surface (MT,PT) inspections of weld joints on each and every flange. These inspections are carried out in accordance with ASME Section V, VIII or API 1104. Through the utilization of certified inspection reports and traceable heat codes, it is possible to acquire a comprehensive tree of the product's lineage. Carbonsteelflanges is able to surpass not only the code but also the customer's expectations regarding the quality of the product.

Value-added services that are additional

The provision of value-added services that extend beyond the scope of standard flanges, Carbonsteelflanges offers its customers. Comprehensive engineering submittals, specialized testing, protective coatings, and individualized solutions are all included in these services. An experienced team is now available to provide assistance to customers throughout the entirety of each project, particularly for the purpose of designing flanges or providing assistance to each individual customer.

A Proven Track Record in the Industry

For more than twenty years, Carbonsteelflanges has been providing its services to the most prestigious multinational clients all over the world. The company is a well-established flange manufacturer with its headquarters in China. The organization has a comprehensive understanding of the stringent requirements that are imposed by industries such as the maritime industry, the petrochemical industry, the oil and gas industry, and the power industry. Carbonsteelflanges is widely regarded as the most dependable supplier due to the extensive application expertise they possess and the impeccable quality track record they have established.

Deliveries that are both prompt and dependable

Carbonsteelflanges maintains a large inventory of sizes that are frequently ordered and have lead times on stock items that are as short as two weeks. In addition, the company keeps a large inventory of sizes. By engaging in optimized production planning and maintaining stringent vendor management, it is frequently possible to achieve compressed schedules when it comes to non-stock or custom orders. This is because of the fact that these orders take longer to fulfill. Products are delivered to projects in a timely manner as a result of the existence of competitive overseas shipping and the availability of reliable estimated times of arrival.

Many Different Requests

Flanges from the Carbonsteelflanges Series B are intended to provide a safe connection between various pieces of machinery, including pipelines, vessels, reactors, heat exchangers, and other instruments of vital importance. These flanges are universally applicable to a wide range of applications in the industrial piping industry. The following are some of the most frequently provided services: hydrocarbons, chemicals, water, cryogenics, compressed gases, and corrosive fluids. Cryogenic temperatures up to 500 degrees Celsius and up to 2500 pounds per square inch are the operating conditions that can be encountered. In many cases, the lifespans of the equipment are longer than the lifespans of the equipment.